The complete design is of the heater is designed as per India standards

mentioned in

IS 13306 : 1992 (INDIAN STANDARDOIL AND GAS

FIRED

THERMIC FLUID HEATERS – METHOD OF CALCULATION OF FILM

TEMPERATURE)

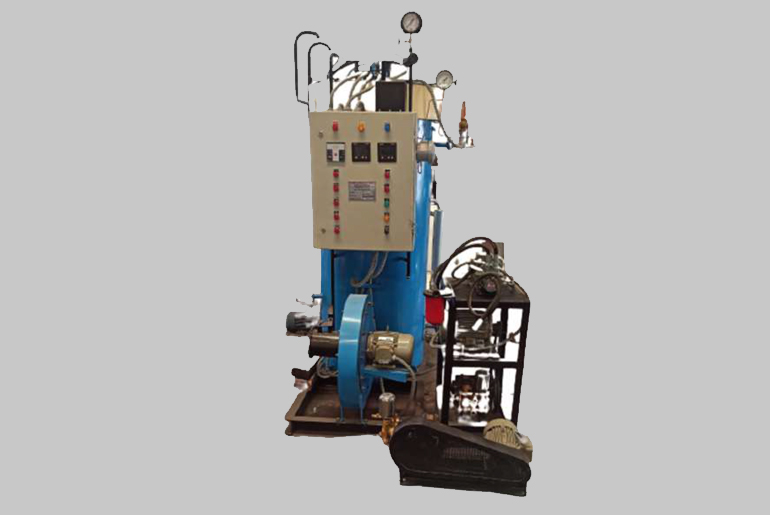

THERMO ENGINEERING WORKS

Established in 1991 by Mr. Redrouthu Ramesh Babu with the vision of providing the quality product and support, having worked with THERMAX GLOBAL his experience has turned the company around, ....

Learn MoreYears Of Experience

Copyright © 2023 Thermo Engineering Works. All Rights Reserved.

Designed & Developed By Tradebizz.in